Description

In 2001, BNSF Railway turned to Trinity Railcar for a modern reefer car. Trinity built 810 reefers in the first group and another in 2003 with both groups measuring 82’ long and 17’ tall. Another 250 were built for JR Simplot with JRSX reporting marks. These modern reefers handle commodities like meat, vegetables, fruits, and frozen food. In addition to these specific usages, these unique reefers can be found in almost any BNSF manifest train as well as on any of the major railroads in the United States.

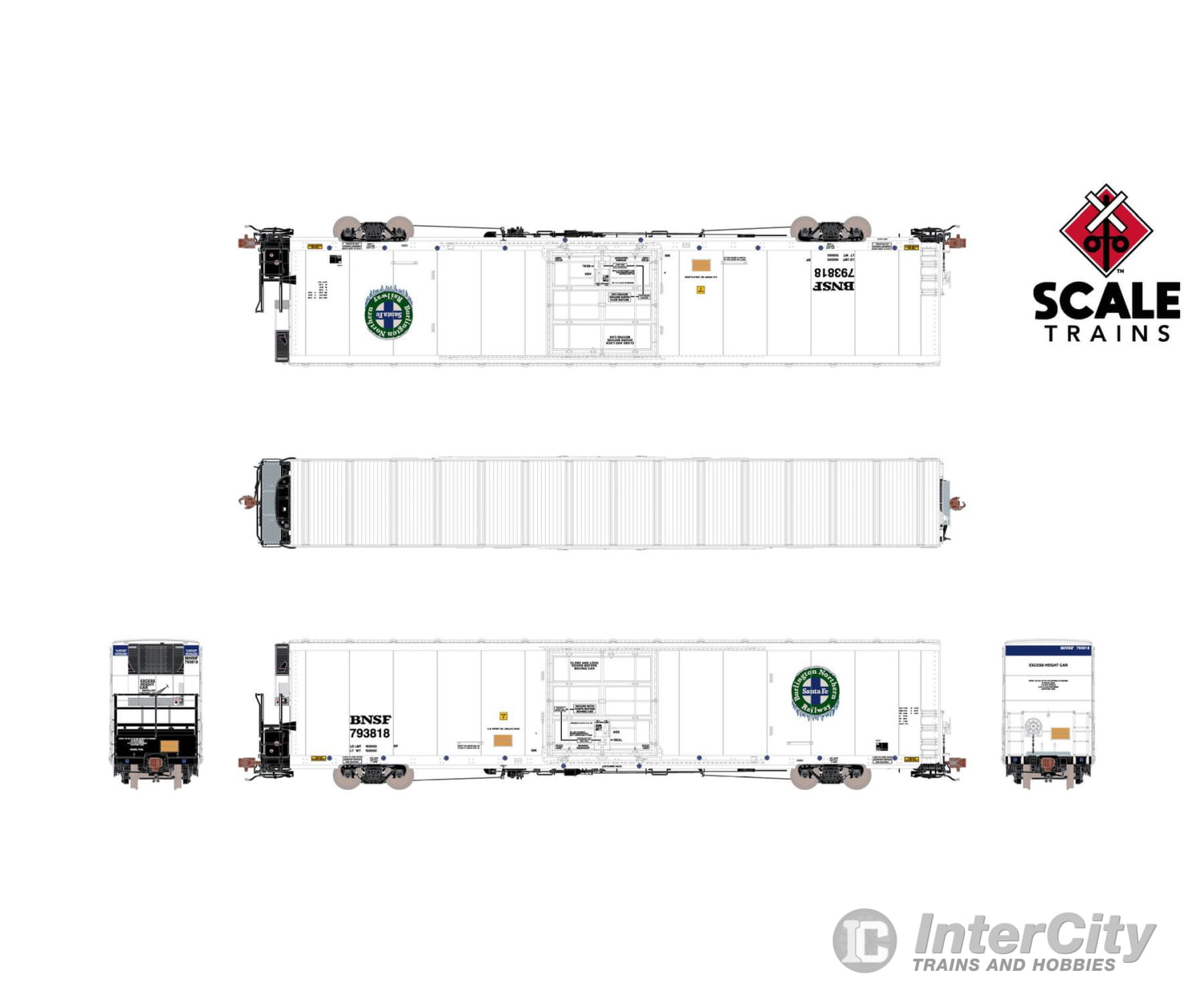

The new ScaleTrains™ HO Scale Rivet Counter™ HO Scale Trinity 82’ Reefer Car model captures the railroad, road number, and era-specific™ features of the prototype – such as smooth or ribbed rooflines, refrigeration unit and fuel tank variations, two side door types, intricate underbody detail, and much more. We’re also offering sound-equipped versions with a track powered, rechargeable battery included. Sound versions feature an operating LED-lighted control panel for the first time in HO Scale.

Road Number Specific ScaleTrains

- Era: 2004 to 2007

- BNSF Series 793810 to 794112; built 6-10:2014

- Fully-assembled

- Multiple road numbers

- 82’ 7711 cubic foot smooth side body

- 12’ plug door with recessed tops section and separate door rods and door handle

- Carrier HVAC unit

- Square Refrigeration unit fuel tank

- Intricate A end refrigeration unit access platform with photo-etched metal platform deck

- Fuel tank end cage with separate plastic frame and wire grabirons

- Ribbed Roof

- Underbody brake rigging and components located specifically to match the 7711 cubic foot car

- Factory-applied ladders, metal grab irons, tack boards, coupler cut levers, and trainline hoses with silver gladhands

- Brake wheel, stand, and chain

- Brake plumbing with separate air reservoir, control valve, and retainer valve plus separately applied wireform plumbing including trainline pipe with brackets

- Photo-etched stainless-steel see-through Morton (stamped round hole) coupler crossover platform on B end of car

- Semi-scale coupler boxes

- Durable body-mounted die-cast metal semi-scale lower shelf Type E couplers

- Highly-detailed ASF Family of Trucks (FOT) 100-ton trucks with finely rendered raised foundry data; rotating black Timken three-sided bearing caps; separate “truck-mounted brake” brake beams; and side bearing detail

- Printed reporting mark and road number on all four trucks

- 36” machined metal wheels with accurately profiled .110” wide wheel tread

- Operates on Code 70, 83 and 100 rail

- Printing and lettering legible even under magnification

- Weighted to Industry standards for reliable operation

- Packaging safely stores model

- Minimum radius: 22”

- Recommended radius: 24”

Sound equipped versions feature:

- Track powered, capacitor circuit

- Operating Led-lighted control panel

- Sound turns on and off via a magnetic reed switch inside the car

- Adjust the volume by pressing a button on the bottom of the car

The first perishable shipments on America’s railroads were simply loaded into boxcars, packed with ice, and covered in thick layers of straw or sawdust for insulation. These were short hauls and not altogether successful. Perishable traffic did not take off until the introduction of ice bunker refrigerator cars, commonly known as reefers. In the bunkers at each end of the car, combinations of ice blocks up to 300 pounds each, chipped ice, and salt served to cool the perishable load in the center part of the cars. The ice was replenished or topped off multiple times while the car was in transit.

Advances in mechanical refrigeration led to small diesel engines powering mechanical refrigeration units built into the ends of the cars. In the 1950s, mechanical reefers began to rapidly replace ice reefers. Further advances lead to compact mechanical refrigeration units mounted on the ends of truck trailers and containers. Since these were much more efficient and powerful than the old diesel reefer units, many older mechanical reefers were refitted with these “truck” units. The latest development in reefer cars are the large hi-cube reefers with end mounted “truck” units operated by BNSF Railway and Union Pacific Railroad, as well as some leasing companies and private owners.

From the railroad companies' perspectives, reefers had two main problems. One was perishables such as meat, produce, and frozen food tend to be a lightweight load when compared to many typical boxcar loads. On the other hand, the ice bunkers or mechanical reefer units took up considerable space. Adding to the demand for space was the fact that a wooden or steel box needs insulation to make the refrigeration work properly. As a result, a typical 1940s boxcar had a 3,800 cubic foot capacity, while a reefer had a 2,000 cubic foot capacity. That was one reason why mechanical reefer went to 57’, while the standard boxcar stayed at 50’. Even then, the boxcar typically had 5,000 cubic foot capacity while the reefer was about 4,000 cubic feet.

BNSF and its predecessors, Santa Fe (ATSF) and Burlington Northern (BN), had extensive involvement with reefers. ATSF had the largest railroad fleet of ice reefers, second only to Pacific Fruit Express. ATSF’s reefers hauled produce from California’s San Joaquin Valley, Southern California, and Arizona’s Salt River Valley (Phoenix area) to eastern markets. The orange crop was the most famous of this traffic, but the largest commodity was the annual potato harvest from the area around Bakersfield. BN and predecessors also handled considerable potato traffic from the Pacific Northwest as well as apples and other produce. From packing plants in Iowa and South Dakota came loads of meat and meat products over BN tracks. Santa Fe also handled some meat shipments from Kansas to eastern destinations.

Operating an outdated fleet of 1960s and 1970s built reefers that were reaching their age limits (and were technologically obsolete), BNSF turned to Trinity Railcar for a modern reefer. In 2001, Trinity built 810 reefers with a 7883 cubic foot capacity. Another group followed in 2003 with internal modifications that gave them a 7711 cubic foot capacity. Both groups of cars were 82’ long and 17’ tall. One of several commercial HVAC unit types, along with a 300-gallon fuel tank, were mounted outside the car body on the A-end. Heavy insulation lined the inside of the car body. Another 250 of the 7711 cubic foot cars were built for JR Simplot with JRSX reporting marks.

These modern reefers handle the same types of loads their ice-bunker and mechanical predecessors hauled. The hotshot BNSF intermodal from the San Joaquin Valley to Chicago usually has a block of these reefers on the head-end, just as the earlier versions of the same trains had on the Santa Fe since the 1960s. Others handle frozen potato products from Montana, Idaho, Oregon, and Washington over the former Northern Pacific and Great Northern lines. The JRSX cars also handle frozen potatoes from the same areas, usually routed over Canadian Pacific. Although most of the fresh meat traffic has left the rails, BNSF is still using the Trinity reefers to haul meat to the Port of Los Angeles for export to Asia. In addition to these specific usages, the BNSF Trinity reefers can be found in almost any BNSF manifest train as well as on any of the major railroads in the United States.