Description

A Tree Frog Writes History

It's December 16, 1960. On this day road number 18 314 rolled out on the tracks of the GDR State Railroad after an extensive overhaul as a gleaming green painted super steam locomotive. With a maximum speed of 150 km/h / 94 mph and a performance of almost 2,000 horsepower it was now the colorful streamlined star in the rather gloomy gray of the everyday GDR and soon acquired the nickname "Tree Frog". The unit belonged to Max Baumbergs "Zoo", as the locomotive roster for the Halle Research Institute (VES-M) was also called. It had previously written German-German history, when Baumberg, the subsequent VES-M manager, was able to pry the old four-cylinder Baden steam locomotive, road number 18 314, in 1948 from his university friend Theodor Düring in the Western zones. At that time, the high-stepping runner was initially called "Schorsch" probably due to the Bavarian smoke stack brim. In 1961 another green express locomotive joined the unit now called "Jimmo", road number 18 201, to go to the Halle "Zoo". From that time on the two streamlined one-of-a-kinds always attracted a lot of attention among the jet-black standard locomotives. Many anecdotes accumulated around Baumberg's green "animals". When road number 18 314 came out of the shops at some point with a thoroughly green paint scheme, nasty rumors went around that due to scarce resources only the dreary car green was available for the "Tree Frog". Nonetheless this locomotive is a unique one-of-a-kind.

Prototype: GDR German State Railroad (DR/GDR) express steam locomotive, road number 18 314, with coal firing and a type 2´2´T34 coal tender. Rebuilt version as an experimental locomotive of the VES-M Halle (Saale) (Railroad Research and Development Locomotive Management Department). Version with a "Reko" rebuilt boiler and partial streamlining, using the road number IVh as a basis (former Baden IV h). Witte smoke deflectors and inductive magnet on one side included. The locomotive looks as it did around 1962/1963.

Highlights

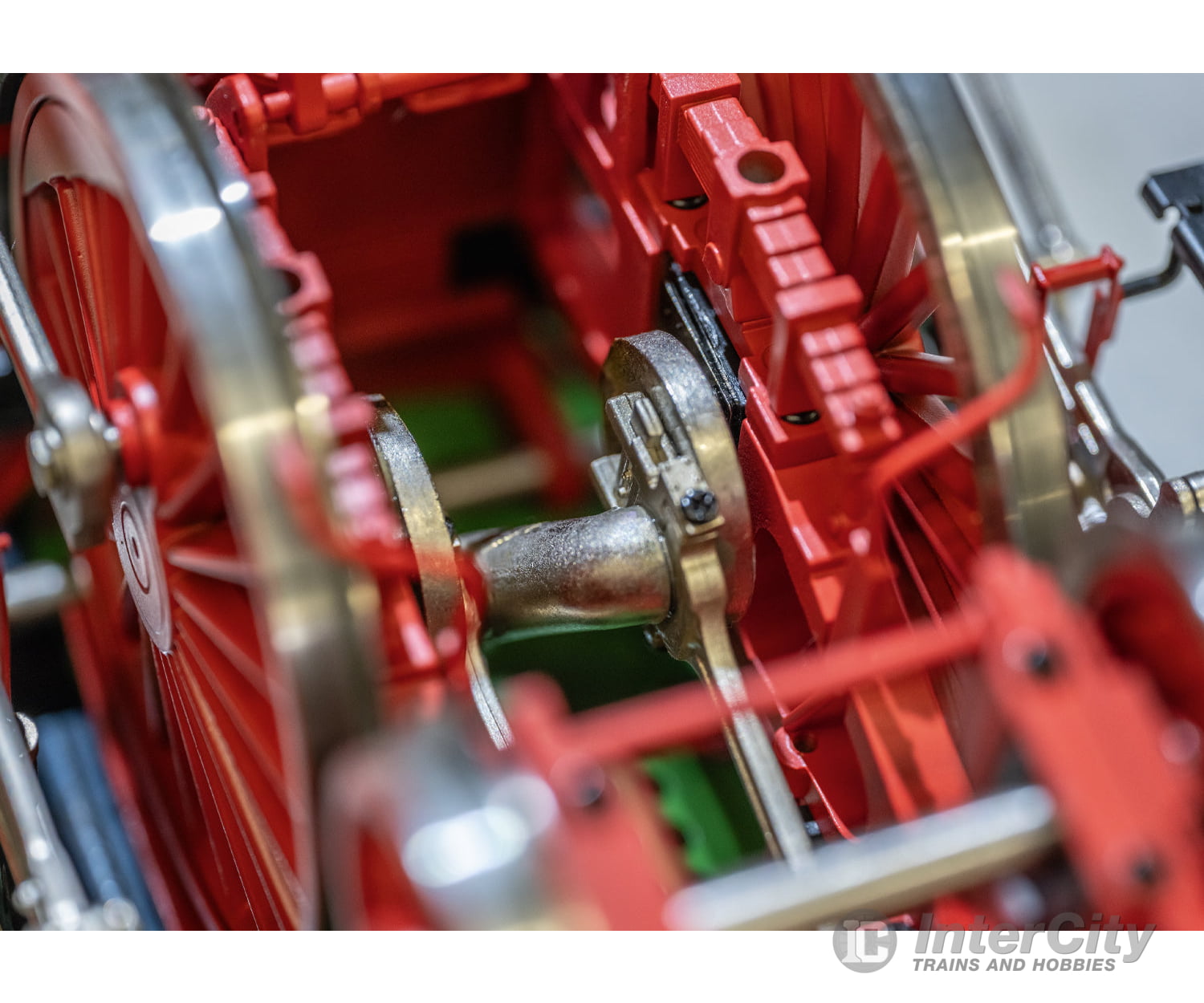

- Completely new tooling.

- Highly detailed full metal construction.

- Frame, superstructure, boiler, etc. constructed of die-cast zinc, separately applied parts constructed of brass.

- Newly developed decoder generation with a current buffer and up to 32 functions.

- Smoke unit with smoke exhaust and f/r cylinder steam synchronized with the wheels and a steam whistle.

- Special function: The locomotive engineer activates the controller (servo activated)

- Load-controlled operating sounds synchronized with the wheels.

- Smoke box door and dome hatches can be opened, many original details included.

- Headlights with a light color correct for the era and warm white LEDs.

- Red marker light that can be controlled.

- Cab lighting.

- mfx decoder for operation with AC power, DC power, Märklin Digital, and DCC.

- Valve gear switchover (forward, reverse, continuous operation) in 3 steps with a servomotor.

- Telex coupler on the rear, reproduction prototype coupler on the front (1 more of each included with the locomotive).

Model: The locomotive is constructed mostly of metal. The frame, locomotive body with boiler, and the cab are constructed of die-cast zinc. Other separately applied parts are mostly constructed of metal (brass). This is an extensive model with many separately applied elements and a highly detailed cab. The smoke box door can be opened. The cab doors and much more can be opened. The locomotive has an mfx digital decoder with 32 functions, controlled high efficiency propulsion, and a sound generator with operating sounds synchronized with the wheels as well as extensive sound functions. It can be operated with AC power, DC power, Märklin Digital, and DCC. The locomotive has a built-in buffer capacitor. All driving axles powered. The locomotive has a built-in smoke unit with smoke exhaust and multi-step cylinder steam synchronized with the wheels and a steam whistle. The locomotive has running gear lights and triple headlights with a light color correct for the era and that change over with the direction of travel. The headlights will work in conventional operation and can be controlled digitally. Maintenance-free, warm white LEDs are used for the lighting.

The locomotive has a red marker light that can be controlled and cab lighting. Digitally controlled special function: The locomotive engineer activates the controller (movement activated with a servo as when the locomotive engineer activates the controller in real life). The locomotive comes with sprung buffers. There is a reproduction of the prototype coupler on the front and a remote-controlled Telex coupler on the rear of the tender, which can be replaced by the other type of coupler. The valve gear switchover is in 3 steps (forward, reverse, continuous operation). There is a built-in figure of a locomotive engineer and a fireman.

An accessory package with a reproduction of the prototype coupler, smoke fluid, and gloves is included with the locomotive. The locomotive is mounted on an aluminum base painted black for display purposes. Minimum radius for operation 1,020 mm / 40-3/16". Length over the buffers approximately 73.8 cm / 29". Weight approximately 9.2 kilograms / 20 pounds 4 ounces.

| ControlUnit | MobileStation | MobileStation 2 | CentralStation 1/2 | CentralStation 3/2* Mobile Station 2** | |

|---|---|---|---|---|---|

| Headlight(s) | * | * | * | * | * |

| Smoke generator | * | * | * | * | * |

| Steam locomotive op. sounds | * | * | * | * | * |

| Locomotive whistle | * | * | * | * | * |

| Telex coupler on the rear | * | * | * | * | * |

| Engineer's cab lighting | * | * | * | * | |

| Sanding | * | * | * | * | |

| Special Function | * | * | * | * | |

| Direct control | * | * | * | * | |

| Sound of squealing brakes off | * | * | * | ||

| Switching range + switching light | * | * | * | ||

| Light Function | * | * | * | ||

| Light Function | * | * | * | ||

| Injectors | * | * | * | ||

| Water Pump | * | * | * | ||

| Sound of coal being shoveled | * | * | * | ||

| Marker light(s) | * | ||||

| Whistle for switching maneuver | * | ||||

| Conductor's Whistle | * | ||||

| Letting off Steam | * | ||||

| Air Pump | * | ||||

| Surrounding sounds | * | ||||

| Safety Valve | * | ||||

| Tipping grate | * | ||||

| Special sound function | * | ||||

| Replenishing fuel | * | ||||

| Replenishing water | * | ||||

| Replenishing sand | * | ||||

| Switching maneuver | * | ||||

| Rail Joints | * | ||||

| Special sound function | * | ||||

| Special sound function | * |